ENVIRONMENTAL RESPONSIBILITY

Investor Relations

We are committed to following practices that will have a positive impact on the environment and the communities in which we operate – for the benefit of current and future generations of employees, customers and shareholders we serve. We respect the environment and take seriously our role as stewards of the planet’s resources.

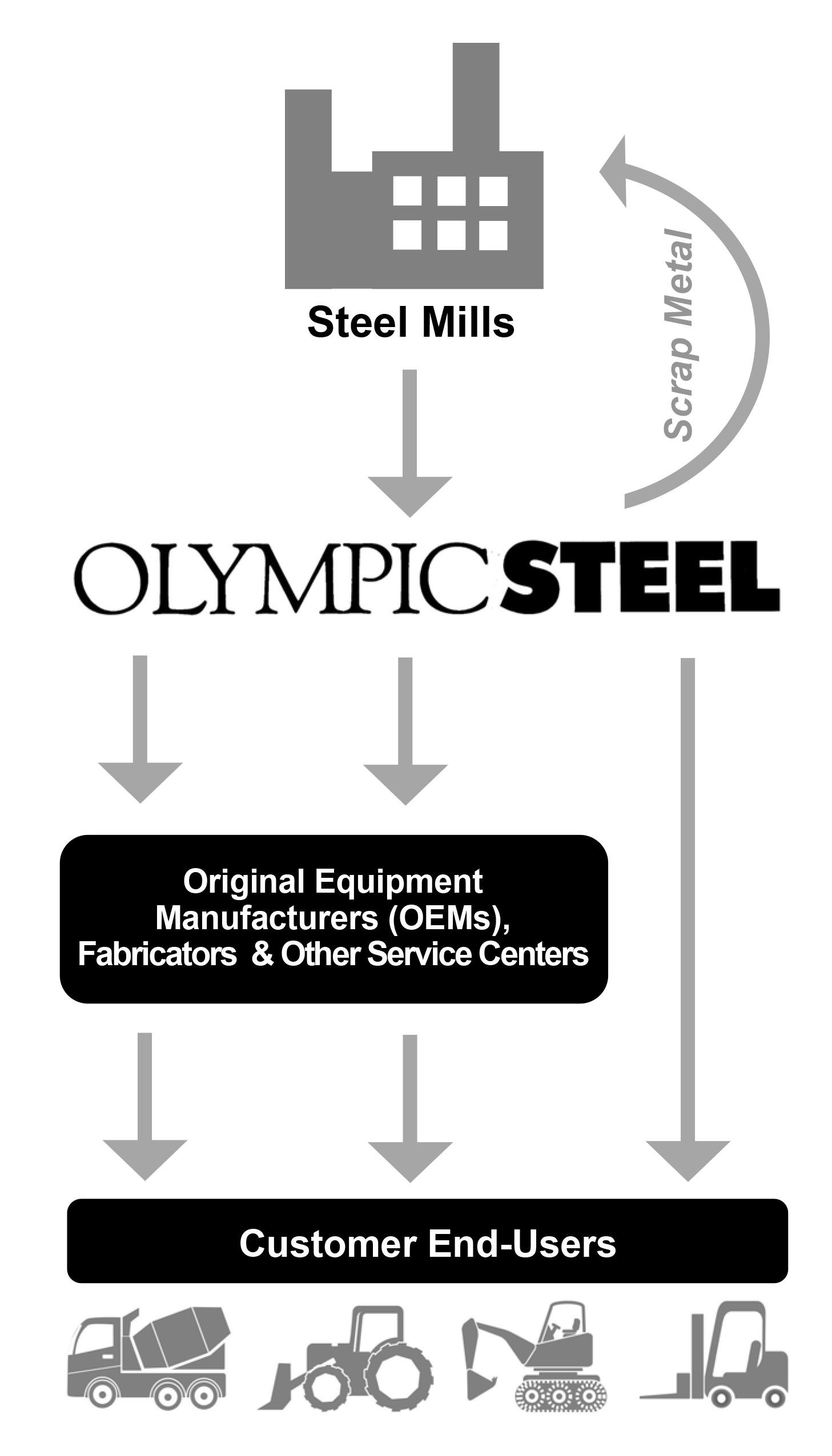

Our Role in the Supply Chain

Olympic Steel is a metals service center. We warehouse, process, and distribute metal products; however, we are not a metals producer. As such, we don’t have the same potential to introduce pollutants into the water or the air that occur during some other metal manufacturing processes. Instead, we’re part of the supply chain that makes products out of metal.

We buy metal products in bulk from metal producers (steel mills). Then, our role as a metals service center is to break that bulk supply into smaller quantities to sell to our customers. We also support OEMs and other customers by cutting, shaping, and otherwise processing carbon steel, stainless steel and aluminum.

While we don’t make metals, we do recycle scrap material that mills re-use in their processes to make raw materials.

Measuring Our Impact

The work we do to process metals for our customers does not distribute pollutants into the water supply, nor do we do any mining or extract any materials from the ground. While we believe our carbon footprint is relatively small, we’re still taking steps to further reduce our overall environmental impact.

Although our environmental impact is low, we are still committed to holding ourselves accountable to further reduce our GHG emissions. We work with a metals industry-specific consulting firm to help us measure our emissions and monitor and effectively implement processes to comply with changing legislation.

Our Environmental Policy

Olympic Steel is committed to responsible environmental management practices. To protect the environment, Olympic Steel commits to comply with all federal, state and local environmental laws, regulations and other requirements relevant to our organization. We commit to the reduction and prevention of pollution by continually identifying opportunities and improving environmental performance in all aspects of our business. Our commitment to protecting the environment is an integral part of doing business and a primary responsibility of each business unit and every employee.

The full policy is available

here.

BY THE NUMBERS

Electricity

Olympic Steel’s electricity consumption is as follows:

- 2019 – 10.53 kwh/sq. ft.

- 2021 – 8.80 kwh/sq. ft.

- 2022 – 8.75 kwh/sq. ft.

- 2023 – 9.02 kwh/sq. ft.

- 2024 – 8.80 kwh/ sq. ft.

To improve our energy efficiency we use lower energy, LED lighting. We are 96% complete in updating to LED lighting across the Company. We are also exploring alternatives, such a solar power where available.

Forestry

While many of our products ship to our customers on wooden pallets, we have taken measures to reduce our reliance on use of wood products. We have instituted pallet return programs for customers in order to maximize the life of a wooden pallet. And, although we incur more upfront costs, we utilize reusable, non-wooden materials to ship products to our customers, where possible. This includes using our own fabricated steel racking.

Our goal is to consistently enhance our efforts and show year-over-year progress, including reductions in usage. We also continue to educate our employees on ways to reduce paper use and have paper recycling programs in place in the majority of Olympic Steel facilities.

We see these efforts as essential to reducing the demand for lumber, which will ultimately lead to a reduction in deforestation.

Metal Recycling

Steel is the world’s most recycled material by weight, and in 2024, Olympic Steel recycled nearly 55,000 tons of scrap metal.

Natural Gas

In 2024, Olympic Steel’s facilities used approximately 1.02 million thermal units of natural gas, which represents a 20% decrease year-over-year due to a milder winter in early 2024.

More than 95% of Olympic Steel facilities use natural gas for heating needs.

We continue to explore opportunities to reduce consumption across all of our locations, including upgrading to high-efficiency generators where possible and using fans and auto-close garage doors in our production spaces to better circulate and conserve heating and cooling.

Renewable Energy

Our energy consultants have calculated our percentage of electricity derived from renewable sources using data from the Emissions & Generation Resource Integrated Database (eGRID) released January 30, 2025. Their calculations show that 19.8% of our electricity consumption was produced from renewable sources (i.e. hydro and wind power).

We expect our renewable content to increase as power companies continue to migrate toward renewable sources. Our electric provider for our Iowa facilities has informed us that 100% of their production comes from renewable wind sources.

Water Usage

In 2024, Olympic Steel used 12,850,405 gallons of water across the enterprise.

We recognize that water is a shared and finite resource.

We commit to preserving this natural resource and minimizing usage by installing water-saving equipment in any newly remodeled facilities, including using low flow toilets and motion-detecting sinks.

We have also significantly decreased our use of disposable water bottles by installing water filtration systems and providing reusable water bottles for employees.

Olympic Steel shares the concerns of Congress and the international business community regarding the use of profits derived from the mining of certain minerals in the Democratic Republic of Congo (DRC) or adjoining countries.

We are committed to the legal and ethical compliance in all of our business practices and do not buy, sell, or use any conflict minerals.

You can view our Conflict Minerals Disclosure

here

LEARN MORE

Find additional information, including our Scope 1 & 2 GHG Emissions, in our most recent Corporate Responsibility Report available here